X300201 TEAM XRAY T4F'20 - 1/10 LUXURY ELECTRIC TC FWD

TEAM XRAY T4F'20 - 1/10 LUXURY ELECTRIC TC FWD

2021 Team Xray All-new Features.

- All-new FWD platform based on the T4’20

- All-new drivetrain layout with centralized motor position

- Central layshaft location for more consistent on-power/off-power balance

- All-new motor position in front of the layshaft for the improved weight balance for FWD class

- Super narrow top shaft utilizes new 20T pulleys and pressed-in ball bearings to minimize space requirements

- Narrow suspension holders and longer arms improve traction and corner speed

- All-new 7mm longer suspension arms feature two shock mounting locations; the lower position combined with ULP shock towers reduce chassis roll and improve stability in high traction conditions

- All-new super low anti-roll bar mounts and new compact linkage components helps lower the vehicle CG

- All-new redesigned anti-roll bar system features new front bars, smaller bushings and shorter ball joints designed for the new low CG mounting locations

- All-new symmetrical top deck shape provides clearance around new central drivetrain pieces while maintaining even side to side chassis flex characteristics

- All-new central motor mount positioned directly on chassis centerline for consistent chassis flex

- All-new black anodized lower bulkheads are moved 1mm inward to increase clearance for new long arm suspension geometry

- All-new narrowed upper clamps to match lower bulkheads and integrate with new shock towers

- All-new lighter graphite floating servo holder and taller servo posts redesigned to work with new suspension and driveline geometry

- Compatible with most T4’20 spares and option parts

T4F Platform.

The T4F is a premium, professional, high-competition RC car for the most demanding racers, developed with attention to detail and backed by premium service & support.

Using our world championship winning T4 platform blended with our latest complete re-engineered T4'20 concept with central drivetrain, we worked with the XRAY R&D team on further improvements of our FWD concept. Based on the experiences gained in the previous racing season with the T4F we have built the all-new T4F'21 based on the all-new T4'20 platform making the T4F the highest-performing FWD electric touring car sharing the XRAY's commitment to engineering perfection, design, performance and support; all made possible by state-of-the-art in-house manufacturing.

Martin Hudy

XRAY T4F designer

Philosophy.

With XRAY's uncompromising commitment to producing the highest quality and best performing vehicles, the T4F captures the unique XRAY character, born of precision craftsmanship, highest attention to detail, and using the finest materials.

Made in Europe.

Designed, developed, and fully manufactured in-house at the XRAY factory in Slovakia, Europe, using precision German and Swiss machines and premium European materials, the T4F is crafted with XRAY's signature attention to detail by our dedicated production specialists.

Central Drive Train System.

The all-new central drivetrain moves the motor and layshaft to the center of the car to improve on/off power stability and to generate more traction.

Everything is new on the central drivetrain system – layshaft, motor mount, pulley, and drive belt.

Motor Mount.

The motor and layshaft mounts are integrated into an all-new one-piece design that is placed in the absolute center line of the chassis. The new motor mount features a pressed-in steel layshaft axle that is positioned in the middle of the chassis. The motor is located in front of the layshaft to match the unique weight distribution needs of a FWD platform.

The motor mount is designed to have super low CG design but still robust enough to resist bending in the serious crashes.

The motor mount is installed on the chassis with 4 screws. One is positioned behind the layshaft axis, with the other three screws located in front. These screws can be removed for further chassis flex adjustment. The motor mount also integrates with the battery backstop holder.

Machined from premium Swiss 7075 T6 aluminum and black anodized.

Middle Layshaft.

The all-new aluminum layshaft is strategically CNC-machined to minimize rotating weight without compromising strength or integrity. The precision layshaft includes two pressed in bearings to minimize runout and reduces drivetrain vibration.

The layshaft features a super narrow design and a new square hub profile to interface with the new 20T pulley for the drive belt. The pulley is secured by an O-ring or the C-clip depending on the driver’s preference.

Machined from premium Swiss 7075 T6 aluminum and black anodized.

Chassis.

The all-new chassis was completely redesigned to accommodate the new center drivetrain system and the long arm suspension components.

The new layout moves the main bulkheads towards the center by 1mm and adds mounting holes for the new long arm suspension mounts.

Chassis.

The 2.2mm thick chassis is CNC-machined from premium-grade graphite material. This chassis is developed for all asphalt surface conditions. The narrow chassis is only 84mm wide with a variety of chassis flex adjustments that help to generate exceptional traction and give excellent steering characteristics.

The 2.0mm thick aluminum flex chassis is CNC-machined from premium Swiss 7075 T6 aluminum, then black coated and laser engraved. The ultra-narrow chassis is 84mm wide and features special cut outs that provide the chassis flex characteristics suitable for medium to very high traction levels. The bottom of the chassis is shaped to increase ground clearance during chassis roll while turning to improve cornering speed.

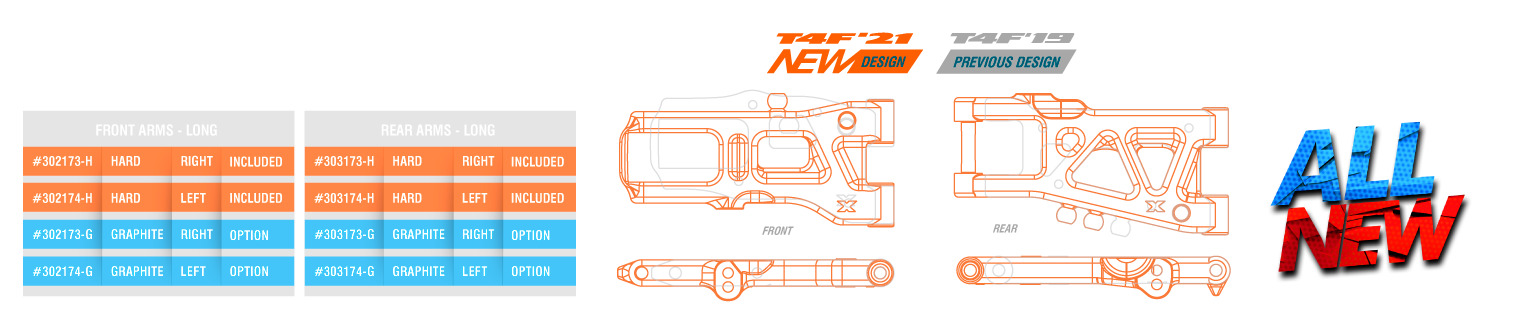

Suspension Arms.

The new suspension arms were completely redesigned. At 7mm longer than the previous generation, they help create more grip in low traction conditions and improve stability on higher traction surfaces.

The suspension arms feature a standard shock mounting position as well as a new 4mm lower position to lower the CG (must be used with optional ULP shock tower). The lower mounting position improves the stability of the car in the chicanes and in technical corners and improves steering response.

The rear arms feature a new design to accommodate the standard rear suspension and the optional ARS suspension using the same arm.

Different hardnesses of arms are available, each optimized for different racing conditions.

Suspension Holders.

The all-new suspension holders were completely redesigned to work with the longer arms.

Made from premium Swiss 7075 T6 aluminum, black anodized.

There are two types of the suspension holders, each specifically designed and chosen to provide the required characteristics – stability, traction, and flex:

• Front of the FRONT suspension – 1-piece.

• Rear of the FRONT suspension – 1-piece for stability, easy to drive in all conditions but especially under high-traction conditions.

• Front of the REAR suspension – 2-piece for maximum rear traction. The holder features a mounting hole for the ARS link.

• Rear of the REAR suspension – 1-piece for more steering and better rotation.

Bulkheads.

All-new bulkheads were completely redesigned to work with the new long arms and narrower suspension holders. The bulkheads feature a super low anti-roll bar mounting position that allows the anti-roll bar wire to be placed under the drive shafts to significantly lower the CG.

The bulkheads feature new milled grooves for the ball bearing hubs to move the bulkheads 1mm closer to the chassis center line from each side. Additional cut-outs create extra clearance to move the inner suspension pins closer to the center line.

Made from premium Swiss 7075 T6 aluminum, black anodized.

Upper Clamps.

All-new upper clamps were redesigned to work with the new narrow bulkhead locations. The upper clamps feature the same 1mm milled grooves for the ball-bearing hubs.

The upper clamps have been further milled to remove unnecessary material to reduce their size and weight.

Made from premium Swiss 7075 T6 aluminum and black anodized.

Steering Plate.

The Swiss 7075 T6 aluminum steering plate was redesigned to significantly reduce play of the entire steering system, making the steering more responsive and precise. The bearings are now factory pressed into the steering plate which eliminates play in the assembly.

Anti-roll Bars.

The all-new anti-roll bar system moves the anti-roll bar wires under the drive shafts to lower the CG as much as possible.

The new anti-roll bar system features redesigned front wire bar length, lighter anti-roll bar bushings, smaller 3x6x2.5mm bearings and all-new lower composite anti-roll bar ball joints to create a super lightweight assembly with low CG.

The wobble-free anti-roll bar system is mounted to the front & rear bulkheads via bearings from the outside of the bulkheads for extra-smooth movement and quick & easy changes and adjustment. The roll bars rotate in ball-bearings for maximum precision and free movement. Anti-roll bar height is adjustable via a screw.

A complete range of anti-roll bar thicknesses are available for tuning, with the front 1.4mm and rear 1.3mm anti-roll bars included as standard. Anti-roll bars have laser-engraved stripes (corresponding to bar thickness) for easy identification.

Spur Gears.

Precision-molded 100 tooth, 64-pitch composite spur gear is strategically lightened to reduce rotating mass. Most popular sizes available for additional gear ratio choices.

ULP Shock Towers.

The all-new ULP (Ultra Low Profile) shock towers were redesigned to work with the positioning of the bulkheads and upper clamps and to match the geometry of the longer suspension arms.

Machined from premium-grade 3.0mm graphite, the shock towers are super lightweight and very compact.

Top Deck.

The all-new top deck was designed to work with the new center layshaft location in the middle of the chassis. Made from 2.0mm graphite material, the shape of the top deck has been specifically designed to achieve maximum traction and great steering characteristics at the same time.

The top deck is perfectly symmetrical to achieve the ideal, consistent flex behavior.

Top Deck Flex Setting.

The unique top deck flex setting allows easy adjustment of the flex between 3 different characteristics.

The top deck can be mounted via connecting stand using these alternatives:

Bumper.

With the BPA (Body Position Adjustment) system, the entire bumper area was redesigned to feature upper & lower composite bumpers. The foam bumper design accommodates the adjustable eccentric body posts as well as the standard fixed body posts.

The redesigned lower bumper has an updated shape with edges that prevent the bumper from touching the surface when the car is rolling.

ARS™ System.

Optional Active Rear Suspension (ARS™) offers additional adjustment possibilities to further tune the driving characteristics.

All-new universal design of the rear arms allows mounting either the standard rear hub or the ARS suspension with no need to change the arms.

The optional ARS aluminum C-hubs were redesigned to work with the new T4’20/T4F’21 rear suspension geometry and are available in 0, 2 and 4 degree caster alternatives.

ARS™ System.

The 0 degree C-hub is recommended for high traction conditions as it generates greater off-power steering, rotation and cornering speed

The 2 degree C-hub angled toward the front of the car helps to generate more traction but in the same time generates more off-power steering and cornering speed comparing to standard rear suspension. Recommended for medium traction conditions

The 4 degree C-hub angled toward the front of the car generate maximum traction. Recommended for very low traction conditions. As the wheelbase will be shorten a lot with this setting, it is recommended to lengthen the rear wheelbase by moving the rear arms back.

There are two alternatives to mount the ARS linkage depending on the desire for increasing or decreasing toe-in when the suspension is compressed.

The link is mounted from the bottom of the steering block to the RF suspension holder. With this setting, the toe-in is decreasing during compression. When the car enters a corner the toe-in is reduced, which increases cornering speed but decreases rear traction. Recommended for medium-high traction conditions.

By adding more shims under the steering block, the rate of change to the toe-in is greater, decreasing the toe-in measurement even more during compression.

Perfection.

Designed in virtual reality using the world's most sophisticated CAD tools, and manufactured using the world's best machining and molding machinery, the T4 achieves a level of perfection in all details that is second to none.

T4F Concept.

All T4 vehicles are typical XRAY: the ultimate professional, high-competition RC car for the most demanding racers, developed with attention to the finest detail, and backed by premium service & support…a luxury masterpiece.

Suspension Geometry.

From the narrow arms, through the tiny front and rear suspension blocks, to the small and robust steering blocks, every suspension part has been specially designed to provide responsive racing characteristics in all racing conditions.

Over the years XRAY has successfully gained and utilized extensive suspension geometry knowledge and self-developed suspension stiffness technology, which have been utilized when designing suspension parts.

The ultra-lightweight suspension parts are molded from a special composite material that makes the parts very light yet very durable to withstand the rigors of high-performance racing.

I.S.S.™ Suspension Bushings.

Using eccentric suspension bushings inserted into aluminum suspension blocks, as well as additional use of suspension shims and suspension parts, the T4 suspension geometry is completely adjustable including:

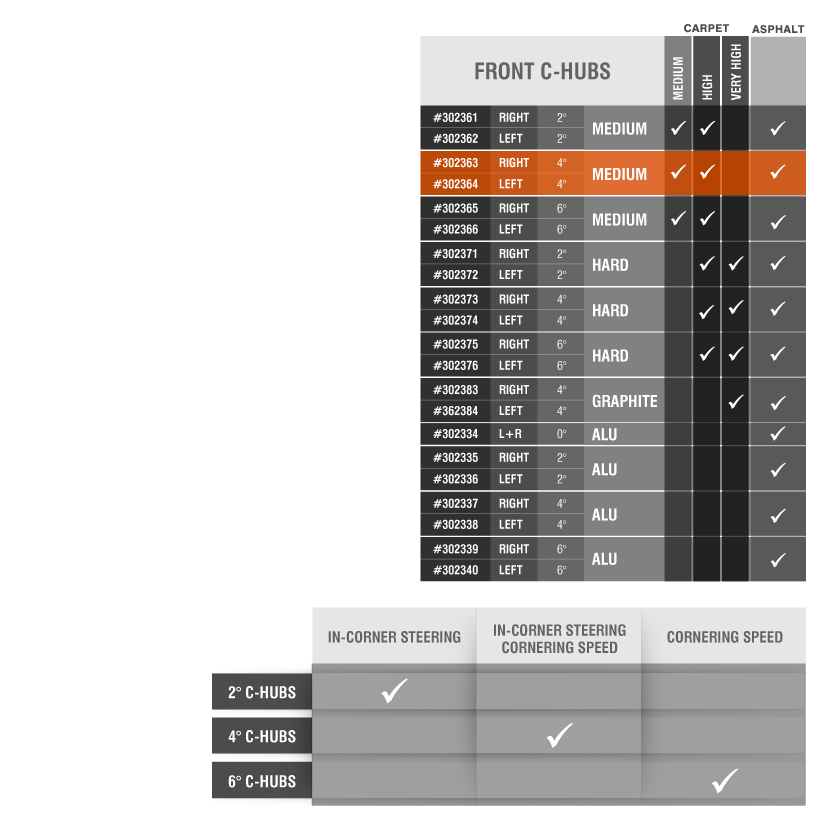

C-hubs.

The C-hubs are available in all standard caster angles (2°, 4°, 6°) and are also available in 4 different hardnesses for various racing conditions.

The C-hubs feature large openings for quicker assembly and maintenance of the ECS drive-shafts. The entire ECS assembly can be easily inserted/removed through the C-hub without the need for disassembly. The added clearance also reduces collisions between the drive-shaft and the C-hub in crashes.

The medium 4° C-hubs are included in the kit which are suitable for the most common track conditions.

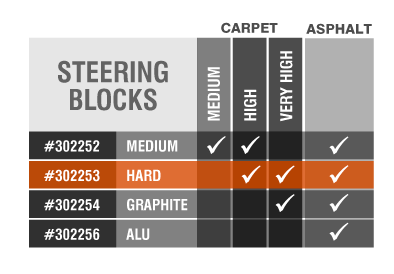

Steering Blocks.

The small and tough steering blocks each feature two Ackermann positions. The front steering blocks also feature small but robust 5x10x4mm ball-bearings to minimize unsprung weight.

The hard steering blocks are included in the kit which are suitable for the most common track conditions.

The steering blocks are available in three different hardnesses to adjust for various racing conditions.

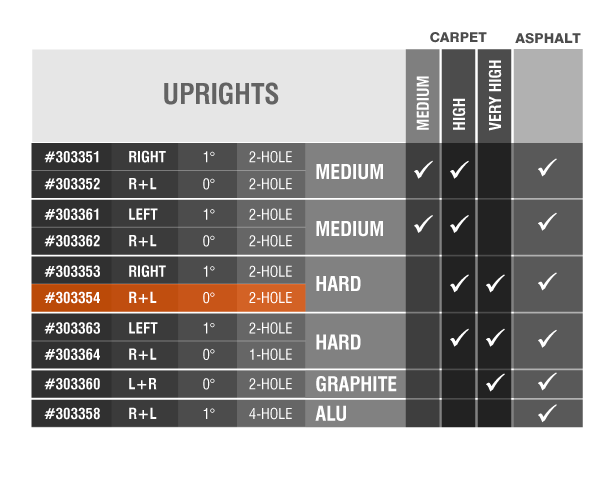

Rear Uprights.

The rear uprights are available in several versions for multiple suspension tuning choices. The Hard, 0°, 2-hole upright is included in the kit for its versatility, suitable in a wide range of conditions.

All molded rear hubs feature small but reliable 5x10x4mm ball bearings to minimize un-sprung weight.

The rear uprights are available in 3 different material formulations blended for different needs depending on traction levels. The hubs are also available with 0° or 1° of outboard toe for different combinations of inboard and outboard toe. Please note that 1° hubs are L/R side specific, while the 0° blocks will fit either side of the suspension.

In situations where the inner and outer ball joint positions of the stock hub create too much or too little chassis roll, the 1-hole hub provides an additional midpoint location to compliment the standard 2-hole adjustments.

Servo Saver.

The popular XRAY servo saver consists of 4 springs which makes the servo saver strong enough to provide the precise steering racers demand, while still being flexible enough to prevent servo damage in hard crashes. The servo saver has interchangeable bushings to fit most popular servos.

ECS Drive Shafts.

The XRAY ECS drive shafts equalize the speed between the drive shaft and the wheel. With a unique 2-piece joint between the axle and the wheel, an extreme wheel turning angle is divided into two shallower angles without causing binding. Regardless of cornering speed and wheel angle, the inner wheel will not bind or vibrate. Drive through the corner is more stable, more precise, and easier.

With the ECS drive shafts, wheel vibrations and noise are decreased to minimum, steering is increased, and cornering speed & smoothness are noticeably increased.

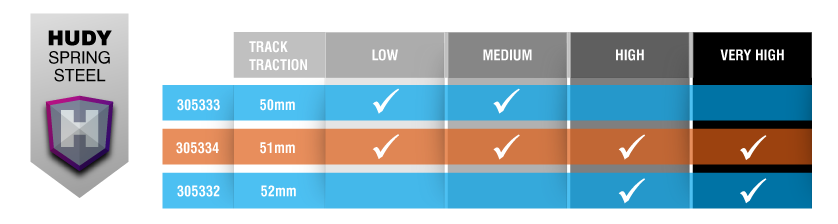

Drive shafts are exclusively manufactured from special world-renowned, HUDY Spring Steel™. The drive shafts are strategically lightened – see the hollow end of the dog bone – to guarantee the lowest possible weight without compromising strength or durability. The drive shafts have been additionally hand-ground for maximum precision and to provide true rotation and unbinding drivetrain operation

Wheel Hubs.

Ultra-lightweight wheel hex drive hubs are CNC-machined from 7075 T6 black-coated aluminum. These ultra-true hex hubs are specially machined to reduce rotating weight while guaranteeing wobble-free wheel mounting.

Optional offsets are available (-0.75, +0.75, +1.5mm).

XRAY Gear Differential.

Complete gear differential set includes composite differential case and cover with pulley. Differential gears are made from tough composite material, precision-molded composite gears combined with light aluminum hardcoated outdrives, which create a lighter and super-smooth gear differential.

When the diff is correctly built there is no need for maintenance for a very long time. There is no need to change oil on a regular basis, and there is no leakage due to the very good sealing system. The gear diff also increases on-power steering which is needed on almost all types of tracks. Works great for both carpet and asphalt tracks.

ULP Shocks.

The ULP (Ultra-Low Profile) shock absorbers make the car easier to drive in chicanes and make it more resistant to traction rolling, letting the car carry more speed through high-traction sweepers. Steering response and overall cornering speed are significantly improved as well.

The shock bodies are CNC-machined from premium Swiss 7075 T6 aluminum and hardened to ensure maximum lifespan. The aluminum upper & lower nuts have a low-profile design, including ULP sealing O-ring and upper composite ball joint.

The piston set includes 3- and 4-hole pistons with 1.0, 1.1, and 1.2mm diameter holes. The pistons are molded using special processes and composites to ensure extreme roundness while maintaining maximum stiffness and durability.

Shock Springs.

XRAY’s full range of existing shock springs may also be used on the ULP shocks, so the T4R can still use the entire range of springs available for the T4 family of touring cars.

The 4S springs - like all other XRAY springs - are manually measured, selected, and matched into pairs to guarantee precisely equal length and damping characteristics.

Steering System.

The dual-arm steering system is supported by six ball-bearings and runs on aluminum stands. Ackermann is easily adjusted by inserting shims between the steering plate and steering rods. The steering system has a low mounting position for the steering linkage, giving the car easier handling going into corners. More aggressive handling is easily accomplished by inserting shims between the steering blocks and steering rods.

Bearing Holders.

The front bulkheads feature integrated belt-tension adjustment through the use of adjustable eccentric bearing holders, eliminating the need for a separate belt tensioner to reduce friction and improve drivetrain efficiency.

The eccentric bearing holders also allow for differential height adjustment. By rotating the diff eccentric holders 180°, the height of the diff can be adjusted by 1mm.

Integrated Adjustments.

Bulkheads feature integrated belt-tension adjustment through the use of adjustable bearing eccentric holders, eliminating the need for a separate belt tensioner. The eccentric bushings allow also diff height adjustment. By rotating the diff eccentric holders, the height of the diff can be adjusted by 1mm.

Ball-Bearings.

A full set of 21 high-speed, blue-sealed and steel ball-bearings are used throughout the drivetrain, steering and anti-roll bars to ensure maximum efficiency. All of the bearings are degreased and oiled with Aero Shell® Fluid 12 for maximum smoothness and long life.

The bearings used in steering blocks have been specially selected to reduce unsprung weight and maximize drivetrain efficiency.

Turnbuckles.

Aluminum adjustable turnbuckles are CNC-machined from 7075 T6 material with a stylish black coating. These turnbuckles are used for front and rear upright linkages as well as for the servo saver. The aluminum turnbuckles are lighter than steel to help decrease the overall weight of the car.

Battery Holders.

Smart battery holders are specifically designed for LiPo batteries and are reinforced for harder impacts. The battery holders prevent the batteries from moving under racing conditions and crashes.

Chassis Balance.

Chassis design focuses on balanced weight distribution and weight transfer. The chassis features pre-drilled holes for additional weights for optimum car balancing.