X370706 TEAM XRAY X1'21 - LUXURY 1/10 FORMULA

TEAM XRAY X1'21 - LUXURY 1/10 FORMULA

2021 Team Xray All-new Features:

- Development focused on improving durability, improving adjustability for better performance on a variety of surfaces, and resistance to chassis tweak after impacts

- Tweak free design improvements achieved with a new rear center pivot mounting system and new pod components

- All-new aluminum center pivot mounting system improves traction and stability of the car, eliminates tweak issues, and provides new adjustment choices to position the pivot point.

- New one-piece bulkheads achieve maximum durability and eliminate tweak issues after a crash

- Graphite rear upper plate redesigned to integrate with the new bulkheads to improve durability and to eliminate tweak after a crash

- All-new graphite chassis side braces offer three different installation settings to alter chassis stiffness to match track conditions

- New chassis plate updated for the rear pivot and chassis braces

- New rear graphite brace integrates with the new side braces and wing mount

- New front upper and lower arms improve strength and reliability while working with the new front tube system

- New front tube system to adjust the stiffness of the front suspension

- New aluminum front anti-roll bar holder lowers the CG

- Longer front kingpins for greater range of front droop adjustment to improve the steering characteristics

- Stealth looking black design

Team Xray World Cup Champions.

Team Xray won the first ever World Cup Championship in South Africa. The dominating performance of XRAY was proven when 9 out of 10 A finalists used the X1 car.

Team Xray Concept.

All parts are purpose-designed and manufactured by XRAY from premium materials including legendary HUDY Spring Steel™, premium Swiss 7075 T6 aluminum, high-grade custom-formulated graphite material, and our own proprietary custom blends of composite materials. Everything on the X1 is premium with maximum attention to detail so all parts fit and work perfectly together.

Team Xray European Champions.

Back-to-Back-to-Back Champions

The 2016 European Championship was the first EC ever where the XRAY X1 dominated the race by placing 5 cars in the A-main; taking TQ honors and having a double-podium finish (1st and 3rd). The XRAY X1 is the first-ever European Champion Formula car with Jan Ratheisky at the wheel.

Since then the X1 has won another European Championships in 2017, 2018 and again also in 2019, making it 4x European Champion for the X1 platform.

Made in Europe.

From unique HUDY Spring Steel™… to the world’s strongest Swiss 7075 T6 aluminum… to XRAY’s own proprietary composite material & premium high-grade graphite materials… everything on the X1 is exclusive and premium.

Using selected, exclusive European materials crafted by XRAY’s engineering artists on state-of-the-art German, Italian, and Swiss CNC machines; the X1 is born from the finest that the world has to offer.

Team Xray ETS Champions.

Back-to-Back Champions

With the most competitive Formula class racing series in the world - the ETS series - the stakes are high for dependable performance during the season at all different tracks across Europe. With the world's best drivers in the Formula class battling for the overall ETS season title, Jan Ratheisky has won the title for the past years 2014, 2015, 2016, 2018 and he reclaimed his title in 2019 with his XRAY X1; making the X1 the most winning & successful Formula car.

Now the rest of the world can own and race the same ETS Championship-winning Formula car; trialed by fire and successfully proven in the most competitive racing series in the world.

Team Xray Winning Heritage.

When it comes to high-competition racing there is absolutely no other Formula car with more outstanding race results and achievements. With national titles around the world from the IIC, ETS & Snowbirds national titles to the World Cup & European Championship titles… the X1 has an astonishingly strong lineup of victories to support the winning heritage of the XRAY X1 platform.

Team Xray Philosophy.

Since the release of the first X1, the competition level of the Formula class continues to rise so it’s no surprise that Team XRAY continues to drive development and push performance boundaries.

With XRAY’s philosophy of engineering & racing perfection, the X1 was designed using the world's most sophisticated CAD, virtual-reality technology. Manufactured using our top-of-the-line, in-house machining; the X1 has attained a level of perfection that is second to none.

Martin Hudy

XRAY designer

Perfection.

The legendary XRAY design, workmanship, material quality and unmatched attention to detail have resulted in a state of perfection achieved by precisely-engineered refinements that create a race car that is easy to drive, work on, and adjust.

Development.

To create and develop the X1 platform, Martin Hudy teamed up with the world’s best 1/10 Formula experts – Jan Ratheisky and Francesco Martini, both of whom have been vital to the development team. They are the driving force for ongoing detail refinement that make the X1 the best handling and performing 1/10 Formula car in the world.

Passion.

As with every XRAY platform, the X1’s success is based on the R&D and Factory Team members’ passion that furthers development and puts out maximum effort at worldwide race events for winning results and constant support to our customers. Jan Ratheisky is the XRAY R&D expert responsible for the X1 platform; traveling around the world not only to showcase the performance of the X1 but to also be available to service and help all XRAY customers. True passion is what drives Team XRAY.

Chassis.

The chassis was redesigned to accommodate the all-new Tweak-Free Pod System and side braces.

The X1’21 chassis continues to offer a wheelbase adjustment using one of three mounting positions for the front suspension. Depending on the installation choice, wheelbase can be selected from the standard length or +/- 4mm alternatives.

The super-narrow chassis creates maximum traction while still having excellent steering and cornering speed. The chassis’ torsional stability also helps eliminate the “scrub effect” in high-speed corners.

An optional chassis plate machined from a stiffer graphite material was developed for very high traction conditions or for tires that offers a lot of steering which makes the standard car more difficult to drive. This optional chassis makes the car more stable and easier to drive by reducing oversteering problems.

Rear POD.

The rear suspension of the X1 incorporates many of the improvements found in the new X12’21 pod design including the all-new Tweak-Free Pod Mounting System. The new pivot system improves traction and stability, and it eliminates tweak issues after crashes.

The all-new pod assembly includes black anodized aluminum bulkheads and revised graphite upper and lower pod plates. The new one-piece rear bulkheads achieve maximum durability compared to previous configurations and use traditional eccentric inserts to adjust rear axle height in ½ mm increments.

The all-new graphite upper plate was redesigned to mount to the bulkheads with centering pins and 4 screws to secure the assembly in proper alignment and to minimize the chances of tweak after an impact on the track.

POD Mounting System.

All-new aluminum Tweak-Free Pod Mounting System improves traction and vehicle stability, plus it helps eliminate tweak issues after crashes. The new system allows for a significantly lowered roll center, a lowered center of gravity, and a new pivot height adjustment using different shims.

The pod mounting position choices include the standard rearward mounting position where the center pivot is located in-line with the side link pivot balls on the rear pod plate, and the new forward location that places the pivot 2mm forward of the link mounting points. This adjustment has a significant effect on the cornering feel:

Forward - Good balance between front and rear traction. Well suited for most conditions.

Rearward - Increases steering and more rotation from rear end. Intended for high grip carpet.

Bulkheads.

The all-new bulkheads are a 1-piece tweak-free design that is more rigid and robust.

The new bulkheads feature centering pins on the top surface that align the upper pod plate during assembly and prevent movement between the components during a crash. To further enhance the assembly’s strength and resistance to tweak, the upper pod plate now uses 4 mounting screws to secure it to the bulkheads

The 1-piece bulkheads utilize eccentric bushing inserts for the rear axle height adjustment.

CNC-machined from premium extra-hard Swiss 7075 T6 black-coated aluminum for extended life and a stylish look.

Rear Ride Height.

The X1’21 bulkheads allow for very quick & easy ride height adjustment using eccentric axle holder bushings. The axle height is adjustable in ½ mm increments over a 5mm range. Smart & easy.

Rear Pod Upper Plate.

The all-new graphite upper plate now mounts to the bulkheads with centering pins and 4 screws to secure the assembly in proper alignment and to minimize the chances of tweak after an impact on the track.

The rear pod upper plate is the base for the center shock and the side tubes. Machined from premium high-grade graphite, the pod plate is very strong and gives rigidity to the entire rear assembly.

The side tubes mount to the rear pod upper plate to control pod movement in standard configuration, and an optional side shock is available for those that prefer the single damper design.

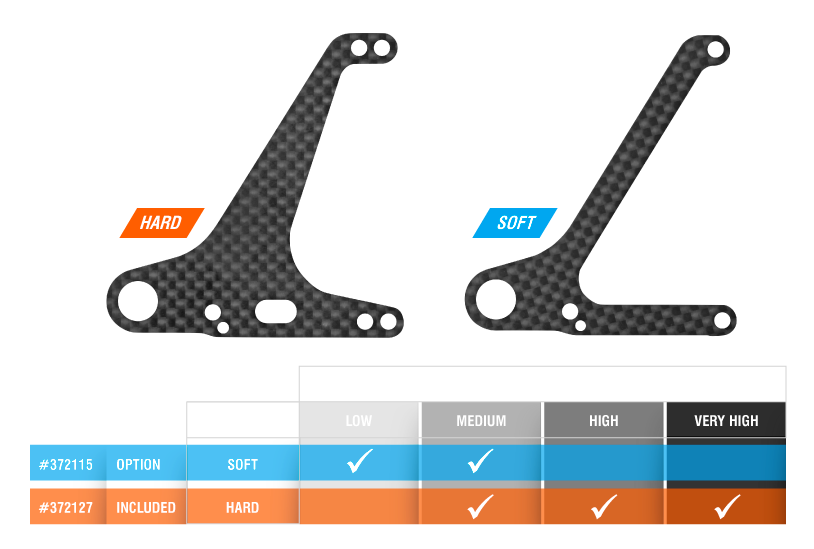

Side Braces.

All-new graphite side braces are mounted to the rear brace, extending forward along the edge of the chassis. The braces are secured to the chassis via aluminum posts and offer three flex settings to alter the chassis characteristics for different track conditions.

Side Brace Chassis Flex Settings.

Rear Link Brace.

To integrate with the new chassis side braces, the rear link brace was redesigned as part of the chassis Multi-Flex system and also functions as the mounting point for the independent wing mount system.

The rear link brace design allows for a wide range of battery placement adjustments and features a convenient O-ring battery mounting system.

The graphite rear link brace is the mounting point for the side tubes and side springs, and functions as a backstop for the battery pack as well.

Front Suspension.

The front suspension was redesigned for improved reliability, strength, lowered CG and improved ease of adjustment. Front upper arms, front lower arms, anti-roll bar mounting system, kingpin axles and mounting stands are all new. The new system features a unique front tube system for a simple roll adjustment for the front suspension.

Front Lower Arms.

The front lower arms were redesigned to allow access to the new front tube.

The shape of the arm is designed to be more robust for improved durability. The extra material reinforces the arm and prevents it from bending in hard crashes. The arm also incorporates an access window to reach the new front tube for easier installation and tuning.

The arm’s special graphite material with a stronger compound hardness reduces flex, increasing stability and improving drivability in high traction conditions.

The front lower arm also features two mounting positions to set the car’s front width.

The softer front lower arms from previous X1 versions are still available as options and are recommended for use on low-traction tracks, or when using harder front tires, to generate more steering.

Front Tube System.

All-new front upper arm allows to mount the front tube which helps to adjust the hardness of the front suspension. Depending on the traction conditions and surface, the front tube helps to adjust front suspension for particular track conditions.

Using thicker oil on the front tube makes the car less responsive but easier to drive and increases stability.

Softer oil improves cornering speed and steering but makes the car a bit more difficult to drive.

Front Upper Arms.

The front upper arms were redesigned to accommodate the all-new front tube system and the new low CG anti-roll bar mounting.

Anti-roll Bar.

The X1’21 features a new aluminum anti-roll bar holder system integrated with the front body and wing mount that lowers the overall CG.

The wobble-free, fully-adjustable wire anti-roll bar system is mounted in holders that are now located on the front wing mount plate via bearings for extra-smooth movement and quick & easy changes and adjustment. The roll bar turns in ball-bearings for maximum precision and free movement. Anti-roll bar height is adjustable via a ball screw.

Kingpin.

The super-smooth, hardened steel kingpins are 3mm longer than on the previous X1 for even greater front droop adjustment range to better set up the car on various traction conditions and track layouts.

Black Stealth.

All aluminum parts are now black anodized for a great stealth looking design.

Standard Features.

Some information shown below may include details from previous kits, and it may vary slightly from current kit specifications.

Chassis & Front Wheelbase Adjustment.

The chassis allows to adjust position of the front suspension by +/-4mm that changes the wheelbase.

MIDDLE: The middle position features the standard X1 wheelbase which is the same as on the previous version cars.

LONG: The long wheelbase is recommended for high traction tracks or large open tracks. The long wheelbase makes the car to turn smoother, improves stability and makes the car easier to drive.

SHORT: The short wheelbase is recommended for low to medium traction tracks or smaller technical tracks. The short wheelbase improves steering and rotation of the car.

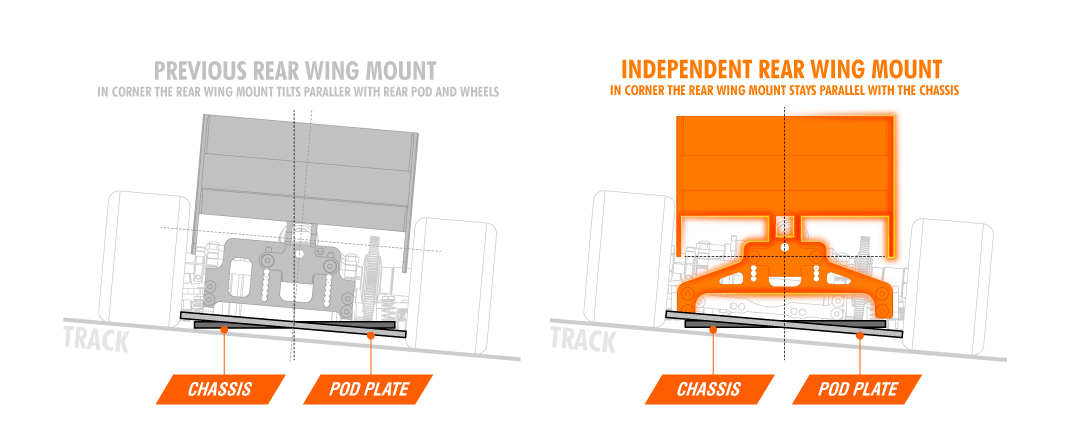

Independent Wing Mount System.

X1 includes the independent wing mount system that allows to install rear wing fully independently from the rear pod plate. When the rear suspension is moving the wing stays in the same position which helps to improve car stability and increases traction, making the car easier to drive in all conditions.

Can be used either with the rear gear differential or ball differential.

Machined from premium 2.5mm graphite material.

Rear Bulkhead Brace.

The rear bulkhead brace connects the rear bulkheads for improved stability of the car. The brace features holes for optional fans and allows to mount the most popular 30mm and 40mm fan sizes.

The graphite brace was redesigned to work with the new independent wing mount system.

Machined from premium 2.5mm graphite material.

Front Stand.

The front alu stand allows to connect graphite arm mount plate with lower suspension arms to increase steering response. There are three different flex settings:

Arm Mount Plate.

Graphite arm mount plates allows to connect post with the steering pivot shaft for greater steering adjustment possibilities. There are two different mounting alternatives with and without the connecting post.

ALTERNATIVE 1 – steering pivot shaft mount is mounted only to the chassis.

This allows the chassis to flex in the steering area which makes the steering smoother but at the same time reduces steering response.

Recommended for large open tracks or tracks with high traction.

ALTERNATIVE 2 – post connected to the arm mount plate.

The steering pivot shaft mount is mounted to the chassis and connected to the arm mount with a bushing. This eliminates the flex of the chassis in the steering area which makes the car more reactive and improves steering response but at the same time can result in oversteering or front tires overheating in some particular conditions.

Recommended for technical tracks or tracks with low-medium traction.

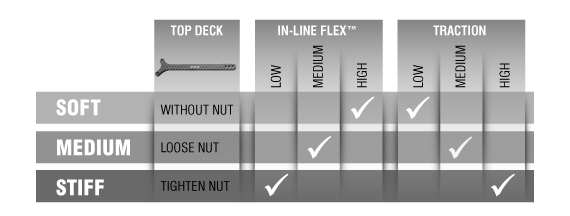

Top Deck.

Graphite top deck is designed to work with the adjustable wheelbase and features three different holes for shock mounting positions depending on the wheelbase setting.

The unique top deck allows for adjustment of the car’s flex using the In-Line Flex™ for different traction conditions and tires. The top deck also features a mounting hole for the shock adaptor when the long shock setting is used.

Side Link.

Alu pod link graphite plate holder replaces the shims. The holder is made from 1 piece and has centering pins to eliminate the possibility to move graphite plate in crashes.

The graphite pod link plate features an additional extra hole for the composite pod link mount to have greater steering adjustment possibilities.

Battery Backstops.

The graphite backstops secured by a nut replace the composite ones to ensure they will not move in a crash.

The battery backstop has 4 positions for more forward placement of the batteries. The distance between each position is 2mm for a total 6mm forward movement of the battery.

The frontward-placed battery makes the car easier to drive, more predictable over bumps & reduces wheel lift in corners.

The rearward-placed battery makes the car more aggressive and increases cornering speed but is more difficult to drive.

Front Track-Width.

The two different, included arm mount plates each have distinct track-width settings.

Narrow track width outer holes on suspension arms and narrow arm plate are suggested when using standard front tire sizes like HUDY or RIDE.

Wide track width – using inner holes on suspension arms and wider arm plate is suggested when using narrow front tires likes Volante. The wide track setting increased track width by 5mm on each side.

Front Coil Springs.

The softer, most commonly-used front coil springs are now included in the kit to make the X1 even better out of the box. These silver C2.0 springs are the most used springs for both carpet and asphalt tracks and improve corner-steering.

Gear Differential.

The revolutionary, all-new XRAY- designed, super-smooth gear diff is a direct replacement for the ball-differential.

Using the optional gear differential makes the car more stable and easier to drive, especially in high-traction conditions. The gear diff increases on-power steering which is needed on almost all types of tracks; a “must have” for every racer.

The complete gear differential set includes a composite case, cover and precision-molded internal satellite gears made from special XRAY-developed composite material; all ensuring long lifespan and super-smooth efficient operation. A super-strong hollow steel shaft ensures maximum reliability and strength.

The advantage of the gear diff is that it is maintenance-free. For a very long period of time, when the diff is correctly built, there is no need for maintenance or frequent oil changes plus no leakage due to the superior sealing system.

Shock Adaptor.

Shock adaptor allows for a more frontward shock mounting position, and when the adaptor is removed the standard rearward position is achieved.

Longer alternative position – which allows for lengthening the shock and mounting the shock on the graphite servo holder – improves drivability over bumps and improves on-power traction. This setting is recommended for low-traction or bumpy tracks.

The standard shock position improves steering response and is recommended for higher-traction tracks.

Shock adaptor allows for quick & easy shock position changes to adjust the downstop.

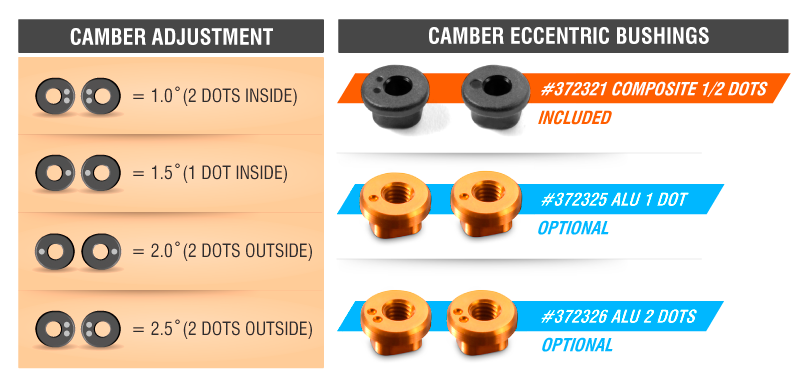

Camber.

Front camber is easily adjusted via front upper arm eccentric bushings.

The kit includes two eccentric bushings; by changing the orientation of the bushings, camber settings of 1.0°, 1.5°, 2.0°, and 2.5° can be achieved.

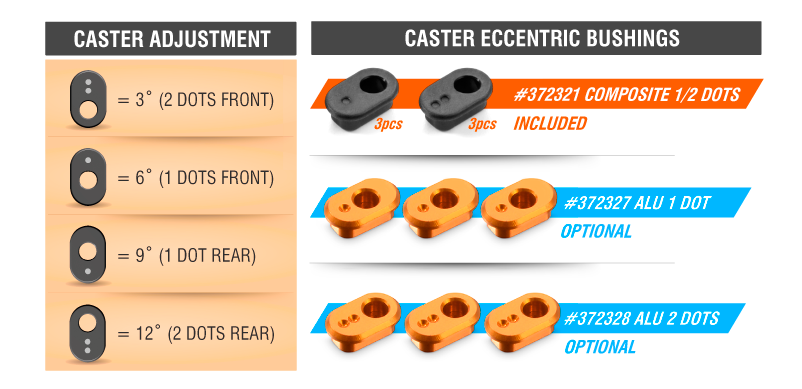

Caster.

Caster is easily adjusted via front upper plate eccentric bushings.

The kit includes two eccentric bushings; by changing the orientations of the bushings, caster settings of 3°, 6°, 9°, and 12° can be achieved.

Steering Blocks.

Steering blocks incudes extra Ackermann position which provides more in-corner steering required mostly at asphalt tracks. The new position has a nearly 100% Ackermann curve to provide maximum steering characteristics.

The super-precise inner hole for the kingpin steel pin ensures wobble-free assembly.

Roll Center.

Front upper & lower roll centers are easily adjusted via included shims. By changing the lower roll center position, the ride height of the car is adjusted at the same time.

Front upper arm roll center is adjusted by inserting shims atop the arm mount plate and alu stands.

Front lower roll center position/ride height is adjusted via shims inserted beneath the front lower suspension arm alu stands.

Ride height can be also adjusted via shims above & below the steering block on the kingpin axle.

Servo Saver.

The tiny yet robust servo saver protects the servo from impact damage. The 4-spring servo saver gives precise steering, making the car easier to drive while giving consistent handling.

Steering Backstop.

The steering backstops mounted on the lower arms allow for the adjustment of maximum steering angle. The advantage of the backstops is that both steering sides can be adjusted to the same angle. Maximum steering angle can be adjusted depending on traction, surface conditions, and tires: under high-traction conditions, the maximum steering angle can be decreased to make the car easier to drive and eliminate traction rolling, or maximum steering angle can be increased for more cornering speed.

Wheel Axles.

Ultra-precise wheel axles are CNC-machined from premium HUDY Spring Steel™ and are additionally hardened and hand-ground for precision fitment.

Side Damper Tubes.

Lateral-damping side tubes provide ultra-smooth side damping, making the car easier to drive and work on. The outer aluminum tube and inner Delrin® tube operate ultra-smoothly.

Side Shock.

The rear pod upper plate and rear link brace allow for mounting of an optional, ultra-precise micro-size side shock which is machined from premium Swiss 7075 T6. The side shock is silicone-oil filled to ensure constant & ultra-smooth damping. The side shock delivers maximum traction, especially in low-to-medium traction conditions.

Side Springs.

Side springs are placed directly on the chassis for smooth and precise movement. Straight side springs have more consistent and smoother compression for smoother out-of corner exiting, and reduction of traction rolling. Optional side springs are available.

Rear Axle.

The ultra-strong lightweight steel axle is used to provide maximum reliability even in serious crashes. The rear axle is hollow for lightest weight while still ensuring maximum strength. The rear differential features high-grade precision carbide balls for spur gear, hardened & precision-ground D-shaped steel shims, and premium carbide axial thrust-bearing.

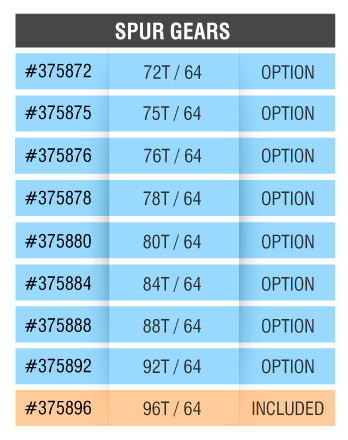

Spur Gear.

The precision-molded spur gear is made from XRAY's exclusive composite material, ensuring true running, super-quiet operation, and robustness for use with powerful motors. A range of optional spur gears is available for fine tuning.

Rear Wheel Hubs.

Aluminum rear hubs are machined from lightweight aircraft aluminum, specially lightened and black-coated for stylish looks. The rear left aluminum wheel hub features a center-balanced clamping mounting system, ensuring secure mounting while eliminating vibration and run-out.

Shock.

The X1 features XRAY short shock from the T4 touring car platform. The unique XRAY aluminum shock absorber has interchangeable internal parts, with fixed 1-piece precision piston which is available with 3 different-diameter holes for damping adjustment: 3 or 4 holes with 1.1, 1.2, or 1.3mm diameter. No matter what you choose, all pistons are ultra-true and round due to a very special mould design, resulting in ultra-free movement of the piston inside the shock body.

Shock.

The aluminum shock body is machined from Swiss 7075 T6 for maximum strength and rigidity.

The shock cartridge has been designed for a self-centering shim to hold silicone O-rings, guaranteeing perfect alignment in the shock body. A finely-threaded aluminum shock lower cap secures the silicone O-rings and shims in the shock body.

A finely-threaded spring preload collar is used for quick & easy spring preload adjustment.

The upper aluminum cap features a small vent hole which makes shock assembly very predictable and easy, since excess shock oil will escape through this vent hole to ensure that the proper amount of the oil remains inside the shock assembly.

A super-soft silicone membrane – supported by a miniature foam pad (inserted inside the membrane) – provides proper damping characteristics.

Progressive Shock System.

The X1 shock allows the use of well-proven optional Progressive Shock System (PSS™) inserts which generates even more traction and steering and is a highly-recommended option part for asphalt surfaces.

The shock insert has 3 triangle cuts and is used with piston without holes. The hardness of the shock is influenced not by the holes in the piston but by the insert. The insert is mounted into the shock with the wider surface on the bottom of the shock and narrower on the top.

When the piston is at the bottom of the shock, it moves softer and dampening becomes harder when the piston is going to the top. This means that the shock dampening is softer in the first part of movement and becomes harder when the car is moving more.

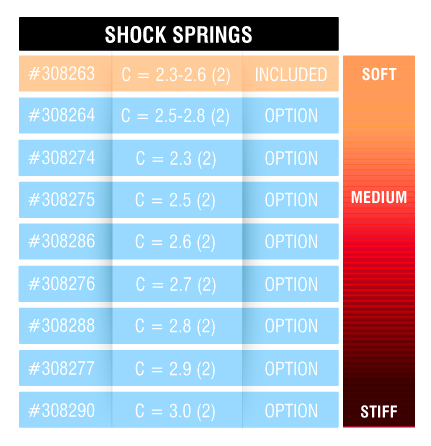

Shock Spring.

To make the car more stable and easier to drive under various track conditions, the new 3S 2.3 linear spring was chosen as the basic setting to provide the best balance between traction, stability, and steering response.

A complete range of optional 3S springs either linear or progressive are available for further fine adjustment.

Turnbuckles.

Steering linkages consist from adjustable 3mm turnbuckles manufactured from lightweight Swiss 7075 T6 aluminum which are used to adjust front toe.

High-Grade Graphite Parts.

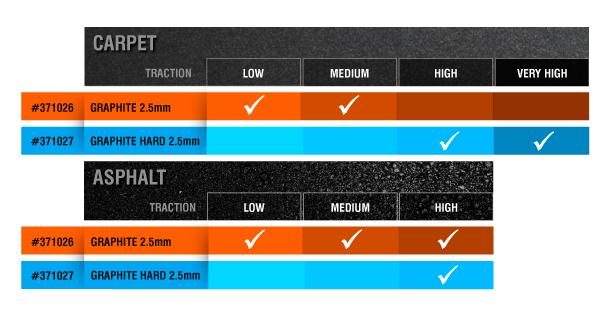

All graphite parts are CNC-machined from custom-manufactured 2.5mm high-grade graphite material with a specially-designed compound for carpet racing and asphalt racing, the X1 handles ideally on either indoor or outdoor tracks, on either carpet or asphalt.

Premium Composite Parts.

All composite parts are manufactured by XRAY using premium self-developed composite mixtures which guarantee sufficient flex of the suspension parts, while being hard enough to withstand hard impacts.

Ball-bearings.

A full set 13 high-speed, blue-sealed, steel ball-bearings are used throughout the drivetrain and steering to ensure maximum efficiency. All bearings are degreased and oiled with AeroShell® Fluid 12 for maximum smoothness and long life.

Body Posts.

Robust body posts have fully-adjustable body holders and are rear posts are mounted on the solid graphite platform on alu stands.

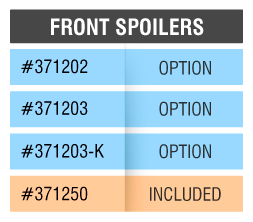

Front Spoiler.

The front spoiler consists of two parts: a composite bumper and a Lexan™ downforce spoiler.

The composite front chassis bumper is very rigid yet flexible, and provides protection where the car needs it most… in the front corners of the chassis where damage may occur from impacts.

The lightweight Lexan™ front spoiler is mounted to the composite front bumper and provides the necessary aerodynamic characteristics. There are two types of spoilers included: low downforce & high downforce, and each are used in particular track conditions.

Rear Wing.

The adjustable rear wing allows for easy adaptation to varying track conditions. The highly-efficient rear wing works together with the X1 racing body, which has air flow channels to direct air onto the wing to help generate rear traction and stabilize the car in chicanes.

The rear wing mounting system features a graphite mount and aluminum stands. Using composite shims between the wing and the alu stands, the wing position can be easily adjusted. The height of the rear wing can be adjusted by changing the mounting position on the graphite plate.

X1 Body.

This high-performance, low-profile aerodynamic body was designed to perfectly fit the X1 and to work under all track conditions while keeping the coveted F1 look and style.

The front and rear of the body have been designed to provide balanced downforce for maximum stability and directed airflow onto the rear wing. The body & cockpit sides are as flat as possible to direct airflow around the body for maximum stability. The body is made from high-quality premium Lexan™ material.

The integrated helmet ensures the body is legal for races where a pilot figure helmet is required.